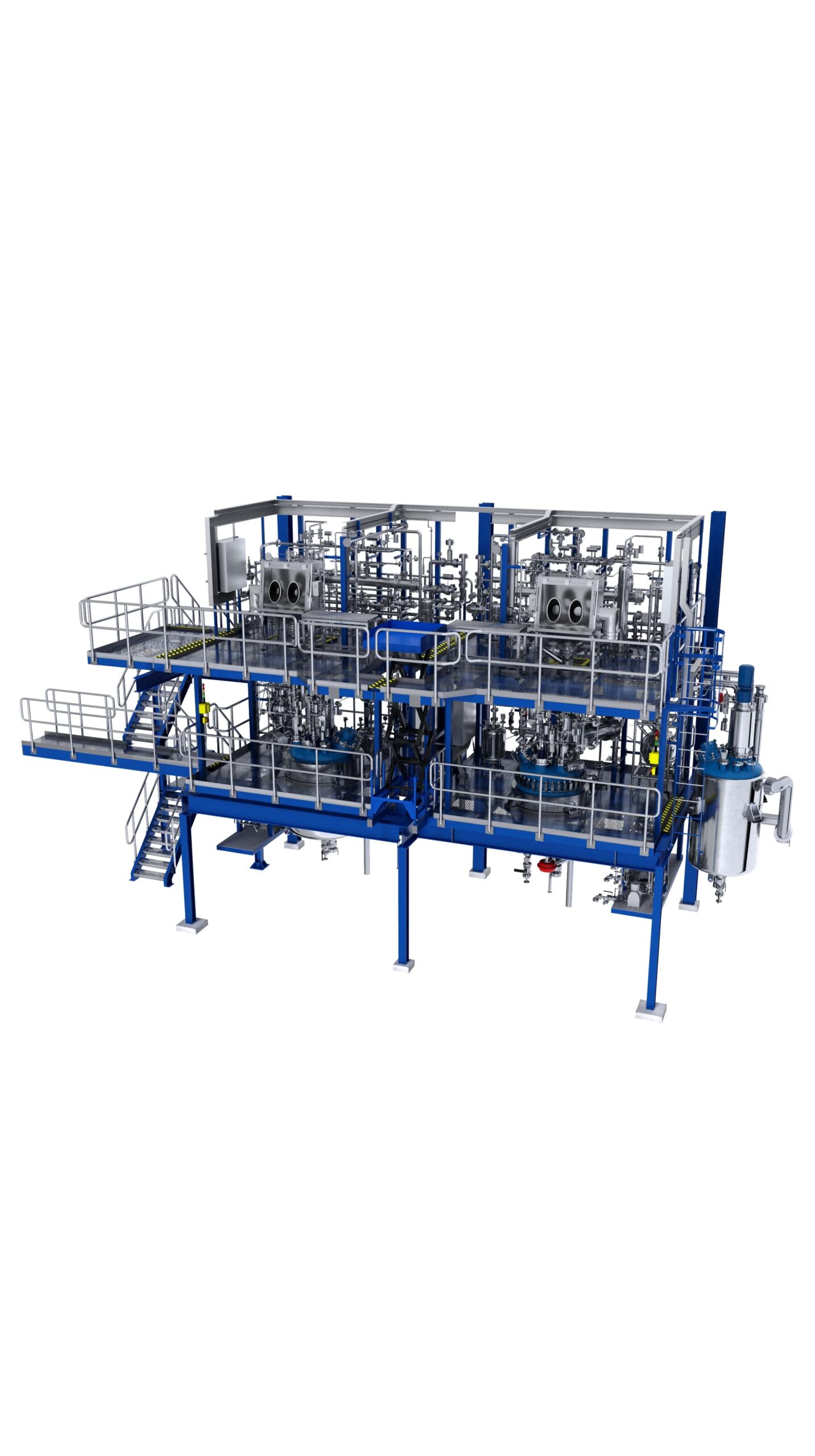

2 stages synthesis skid reactors

Solution

3V Technologies:

Reaction.

3V Competences:

Mechanical engineering, materials know-how, civil works.

Design:

Design a complete reaction plant with two reactors in different materials installed in a metallic structure frame with other process equipment such as borosilicate dosing vessels, heat exchangers, glove boxes, etc.

Build:

Manufacturing of one reactor in stainless steel and one in glass lined carbon steel, fully assemble in a steel skid modular structure; all these equipment connected with process piping.

Operate:

Supporting the client during the mechanical installation phase inside the existing building.

Team

3V project team:

Project Manager, Design Office, Field Service Engineers.

Site of realisation:

Netherlands.

Audience

Client industry:

Fragrances.

Context

Project context:

Increasing production capacity of the chemical-food plant of the client.

Project goal & client needs:

We were contacted by the client for the realisation of a system that could be installed within an existing plant.

Results

Project execution timing:

1 year.

Project complexity:

Match the new steel skid with the existing installation. The success of this specific project allowed us to gain customer trust as reliable supplier generating other projects’ opportunities with other client plants in Europe.