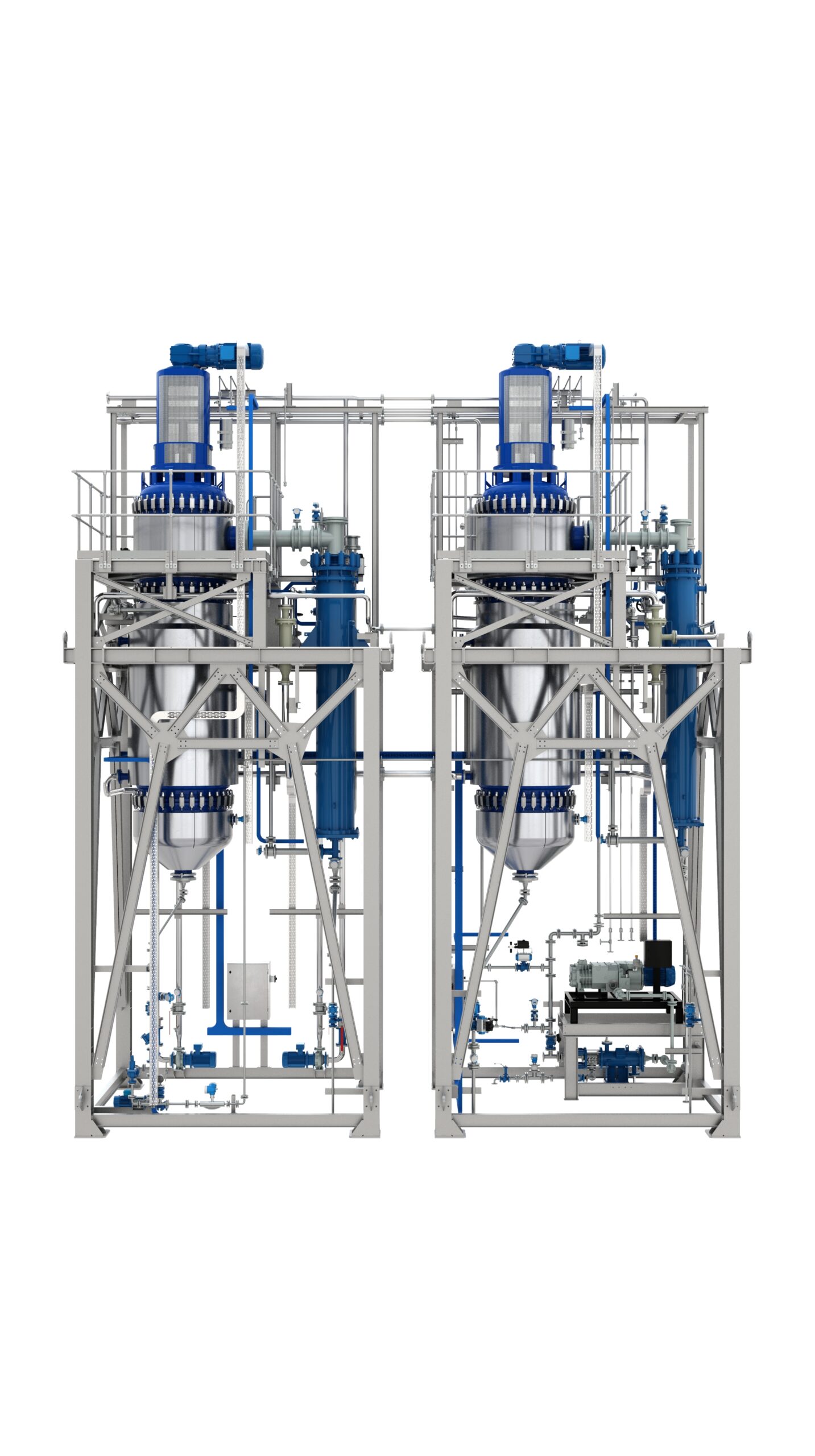

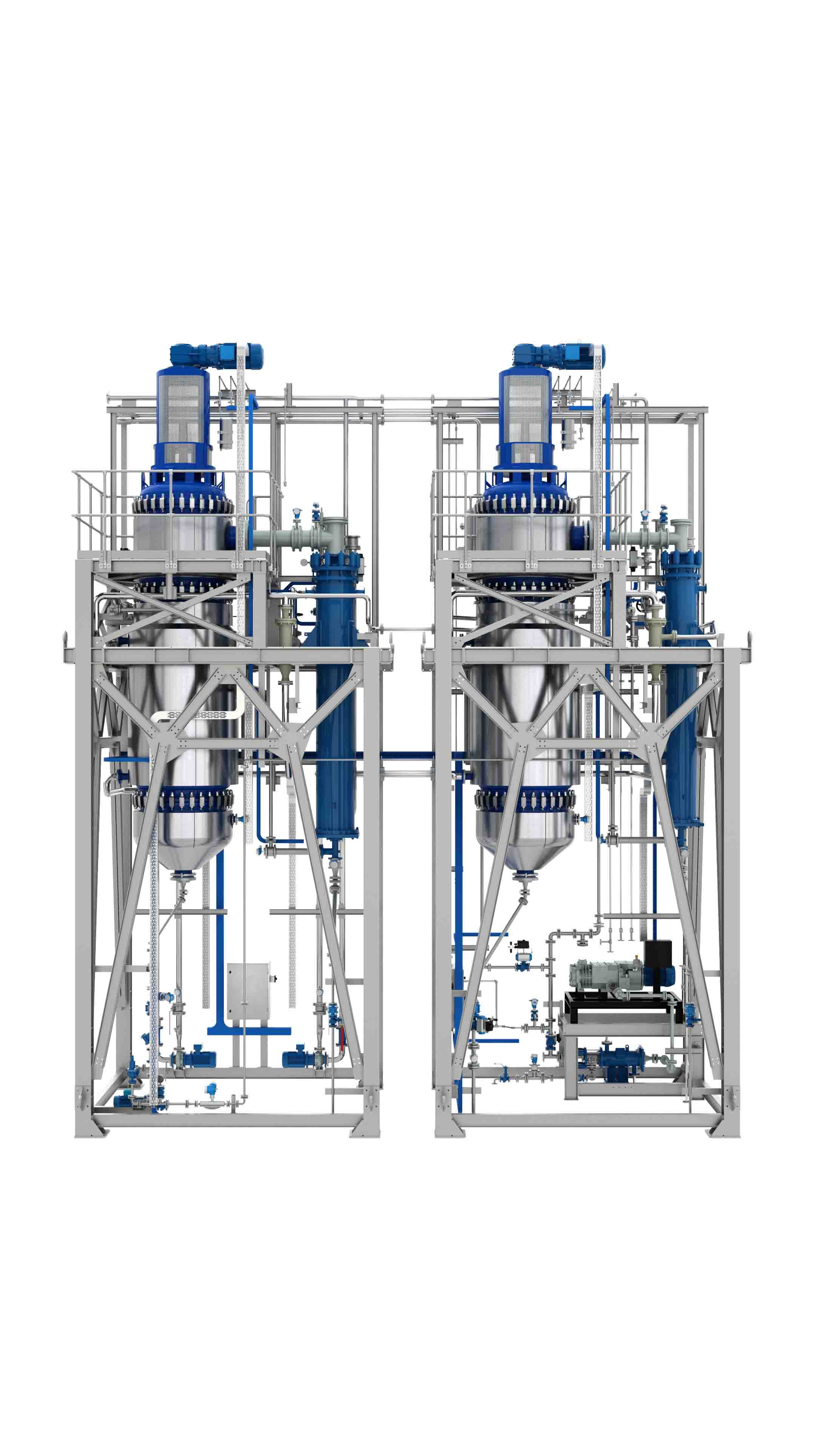

Agrochemical purification plant

Solution

3V Technologies:

Thin film evaporation with internal glass line finishing.

3V Competences:

Ability to configure complete concentration systems for highly thermosensitive products in corrosive environment.

Design:

Definition of operating conditions and coherent sizing of the glass-lined thin film evaporator as well as its ancillaries for a semi-skid assembled solution.

Build:

Build all process equipment and assemble the skid to the maximum degree compatible with site specific handling constraints.

Operate:

Commissioning & start-up of the units.

Team

3V project team:

3V Tech Project Manager, Project Engineering Manager, Document Controller, I&C Engineer, Automation Engineer, Drafter.

Site of realisation:

United Kingdom.

Audience

Client industry:

Agrochemical.

Context

Project context:

Perform the purification of a crop protection chemical with a double stage evaporation plant in a highly corrosive environment.

Project goal & client needs:

Supply of two light skids to be integrated into the customer’s main steel structures. Both of them present a glass lined thin film evaporator including automation system with complete shop pre-assembly.

Results

Project execution timing:

1 year.

Project complexity:

Integration of the plant into an overall layout and structure, with performance guarantees on evaporation capacity and product purity.

Other information

Thin film evaporation under vacuum is the right solution for the concentration of products with a high degradation tendency. The ability to fabricate them with glass lined finishing has made us the ideal partner for this project.

Year: 2021

Final product: unknown

Capacity: 2375 kg/h

Skid dimensions: 3100x3600x7400 mm

Material: CS glass lined

Scope of supply:

- 8 m2 thin film evaporator

- Ancillaries

- Vacuum system

- Feed and transfer pumps

- Complete automation systems connected to customer’s DCS