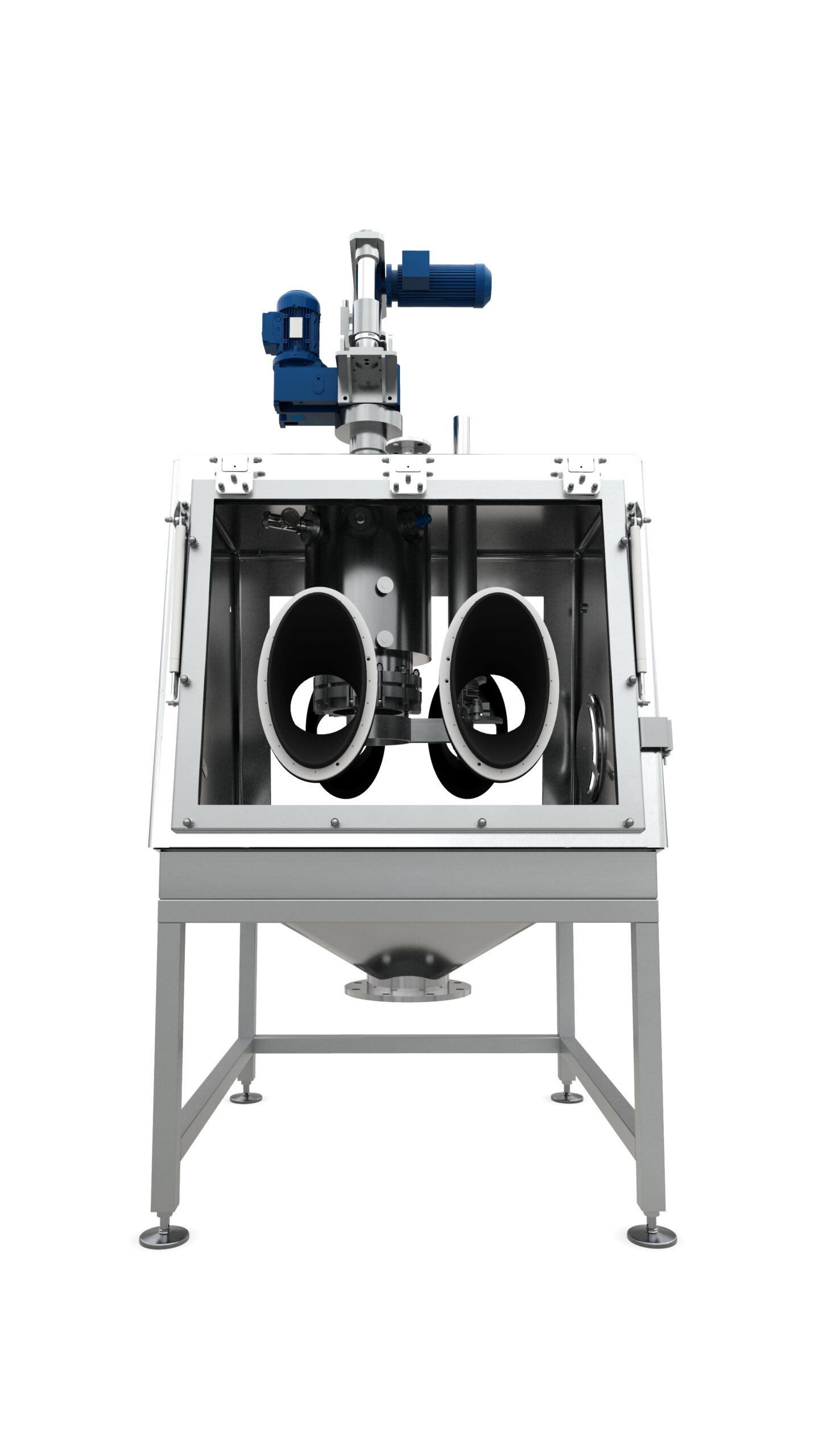

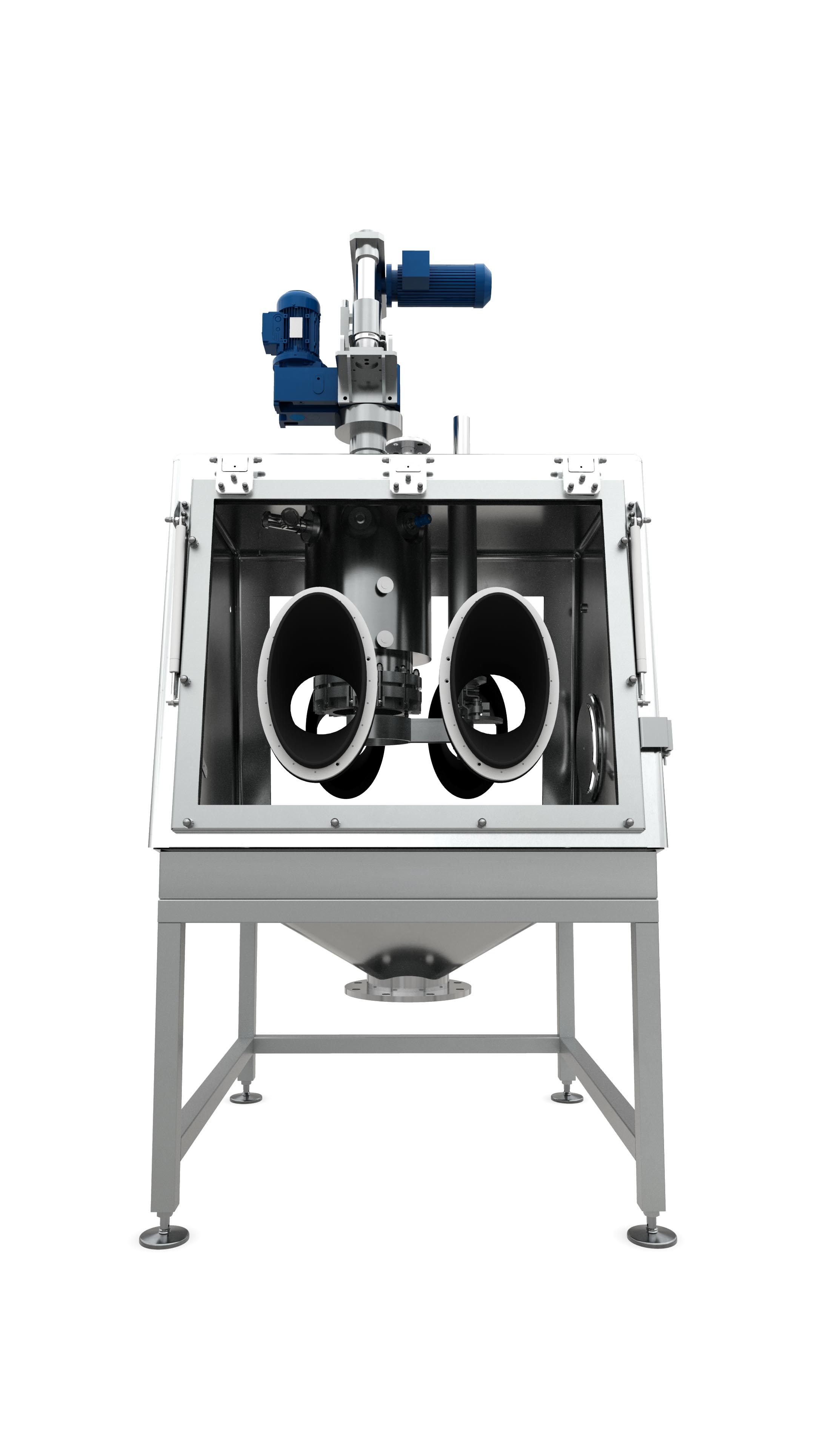

Filter dryer for high potency molecules

Solution

3V Technologies:

Filtration and Drying.

3V Competences:

Mechanical design competences and integration with containment devices.

Design:

Design specific customised solutions in order to achieve high containment performances with an integration of the isolator.

Build:

Build the filter dryer with design criteria suitable for APIs production.

Operate:

Integration with isolator device, commissioning & start-up of the system.

Team

3V project team:

3V Tech Project Manager, Customer Technical Director, Subvendors for structures, ancillaries and all other process equiments.

Site of realisation:

Italy.

Audience

Client industry:

Pharmaceutical.

Context

Project context:

High potent API production.

Project goal & client needs:

We were contacted for a project that needs to ensure high containment conditions and operator protection during work and maintenance.

Results

Project execution timing:

1.5 years.

Project complexity:

Develop specific customised solutions in order to have all key components of a filter dryer inside containment devices such as process connections, base bottom and dust filter.

Other information

An HPAPI is a Highly Potent Active Pharmaceutical Ingredient and can be defined as a pharmaceutical compound with a low occupational exposure limit (OEL). The occupational exposure limit defines the maximum quantity of product an operator can be exposed to within a defined time frame to avoid the risk of short and long term effects on health. A specific value of 10µg/m3 is defined as the threshold limit for the definition of an HPAPI. All compounds with a lower OEL are considered highly potent. As the risk of an adverse effect on human health is the product of a hazard and the exposure to such hazard, risk mitigation of handling potent APIs (high hazard) can only be accomplished through the adoption of containment systems (low exposure).