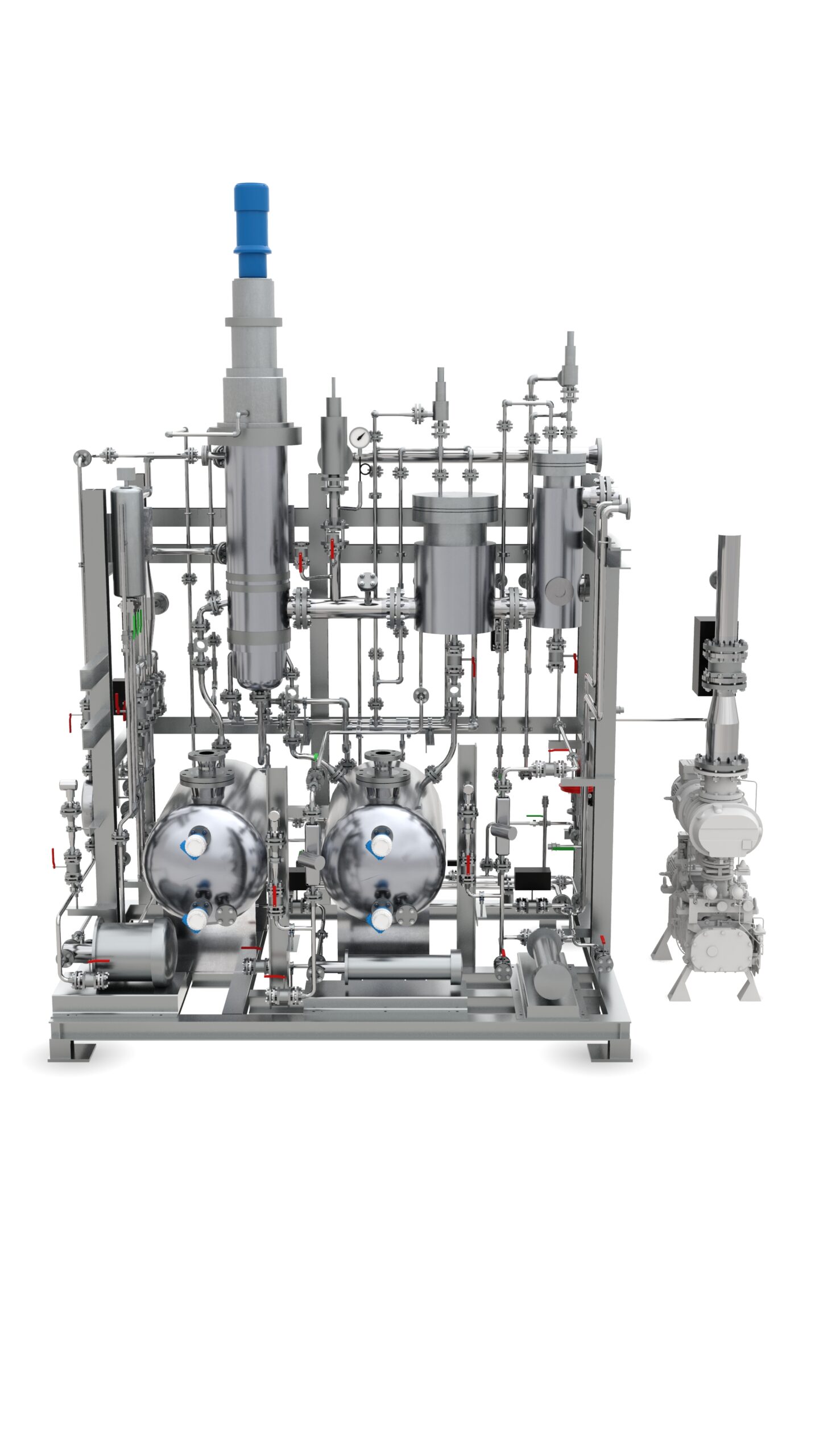

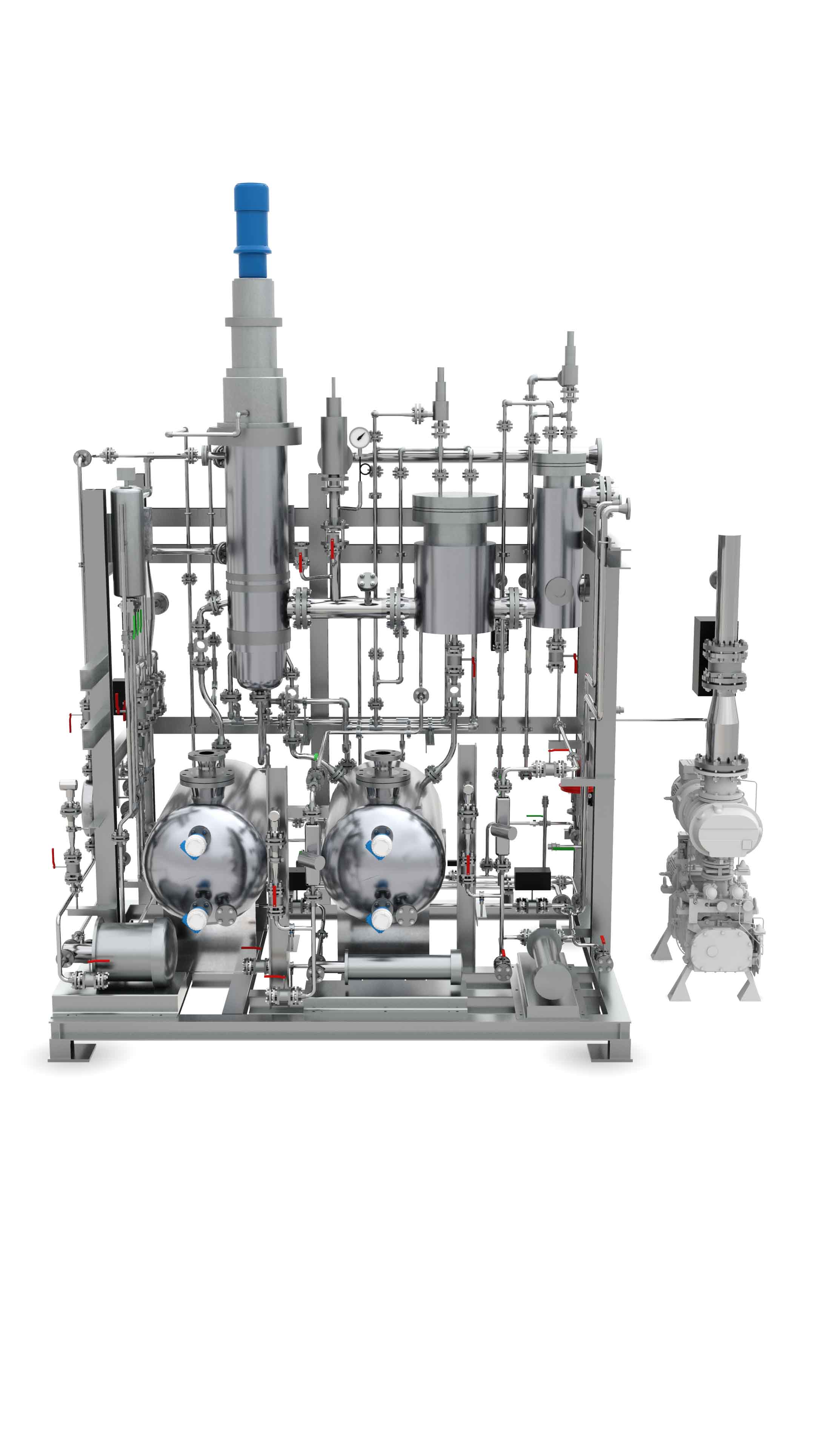

Multipurpose pilot plant

Solution

3V Technologies:

Short path evaporation.

3V Competences:

Ability to configure complete concentration systems for highly thermosensitive products.

Design:

Definition of operating conditions for main equipment and ancillaries for a flexible multipurpose unit in strict adherence to customer’s process requirement and space constraints.

Build:

Build all process equipment and assemble a skid ready for final installation at customer’s site.

Operate:

Commissioning & start-up of the units.

Team

3V project team:

3V Tech Project Manager, Project Engineering Manager, Document Controller, I&C Engineer, Automation Engineer, Drafter.

Site of realisation:

USA.

Audience

Client industry:

Pharmaceutical.

Context

Project context:

Allow internal testing activities with a multipurpose unit for pharmaceutical intermediates purification.

Project goal & client needs:

Supply of a turn-key solution around a short path evaporator including automation system with complete shop pre-assembly.

Results

Project execution timing:

Currently in execution.

Project complexity:

The main complexity of the project is related to the size of the system: a small-scale pilot plant with a sophisticated vacuum system (primary + secondary circuit to reach 10 – 2 mbarg).

Other information

Pharmaceutical intermediates have critical properties that make short path evaporation under vacuum an ideal solution for the concentration of products with a high degradation tendency.

Year: 2023

Final product: unknown

Capacity: 45 kg/h

Skid dimensions: 1500x2700x3600 mm

Material: Stainless steel SS316L

Scope of supply:

- 0,3 m2 short path evaporator

- Condenser

- Vacuum system (primary + booster)

- Receiving tanks (distillate and concentrate)

- Feed and transfer pumps

- Functional specification and control narratives